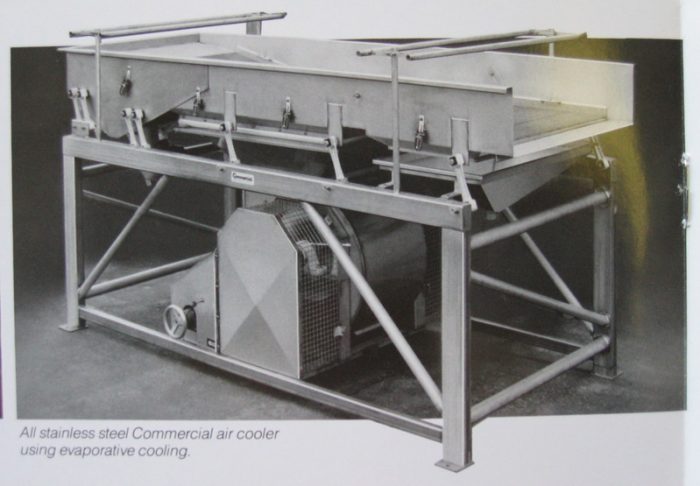

- Air cooling involves sending a chilled stream of air over a thin layer of product

- Floatation bed shakers can blow pre-chilled air up through product

- Air knives can blow pre-chilled air down through product on either a shaker deck or open-topped belt conveyor

- A cooling tunnel can be added to a long belt conveyor to blow slow moving air in the opposite direction of belt travel

- When the product’s final form allows it, adding water sprays above a flotation bed shaker can accelerate evaporative cooling

- Cooling tanks with variable speed belts offer good cooling potential

- Adding a water chiller to a hydro food pumping system can serve to cool the product while it is being transported to its destination

Cool

We have developed several means to cool product depending on its stage in the process or final form. For fresh market product the preferred method of cooling is by air, and for processed product such as frozen or canned foods adding water to the cooling process can accelerate the rate of BTU loss.